About Me

With extensive experience in supply chain industrialization and manufacturing engineering, I’ve successfully led global

initiatives aimed at optimizing operational efficiency, strengthening supplier collaboration, and ensuring the timely

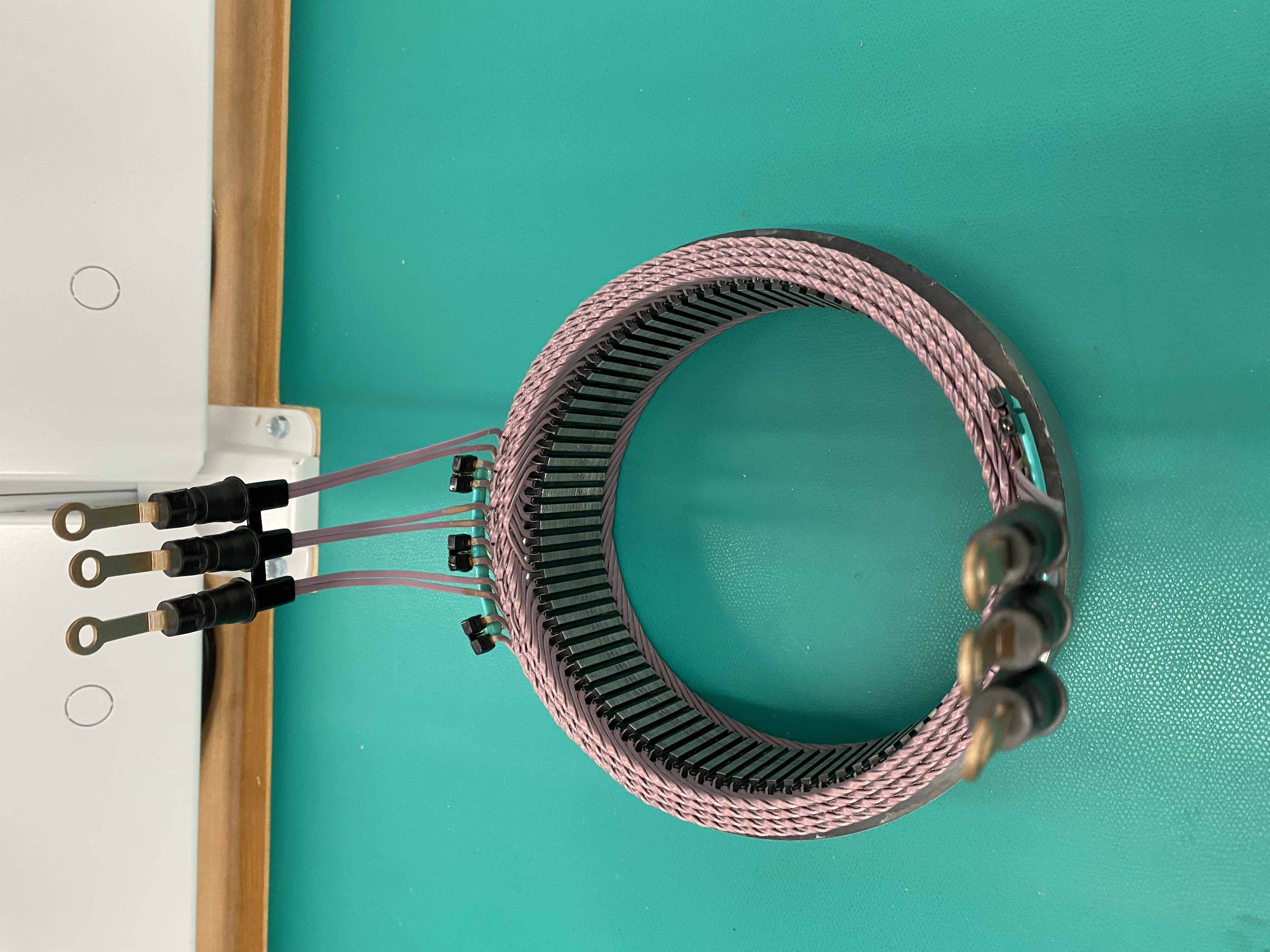

delivery of high-quality products. My expertise spans key areas such as electric engine and lithium-ion battery

assembly, surface mount technology (SMT), high-reliability electronics, and composite material processing. In each of

these areas, I have worked closely with cross-functional teams and suppliers to drive continuous improvement and enhance

product performance.

Through the integration of automation, advanced assembly techniques, and scalable production methods, I’ve been able to

significantly enhance production quality, reduce costs, and shorten time-to-market for new products. By continuously

analyzing data from production lines, I’ve identified opportunities for efficiency improvements and implemented process

changes that lead to measurable reductions in waste and increased throughput. Additionally, my focus on supplier

collaboration has allowed for better forecasting, inventory management, and the seamless integration of new

technologies, ensuring that production cycles are as efficient and cost-effective as possible.

Skills

Experience

Education

- Value Engineering

Lean Manufacturing, Process Optimization, Design For Manufacturability (DFM), Cost Build Up Initiative - Supplier Management

Supplier Assessments / Audits, Process Flowdowns, Monitoring KPIs, Root Cause Corrective Action - Tools & Software

3D CAD / GD&T (Solid Works, NX), Microsoft Office, Siemens Teams Center, Agile - Quality Standards & Tools

ISO9001, AS9100, IPC-610, APQP, PPAP, Gauge R&R, FMEA Methodology

- 2021 - 2024

Supplier Development Manager at Archer Aviation - 2017 - 2020

Supplier Industrialization Engineer at Gogo - 2013 - 2016

Systems Manufacturing Engineer at Lytron - 2008 - 2012

Manufacturing Engineer at Beacon Power - 2006 - 2007

Process Engineer at Satcon Electronics - 2002 - 2005

Manufacturing Engineer at Leonardo DRS

- 2015

MBA, General Management from Clark University - 1999

BS in Industrial Engineering from Northeastern University

My Specialization

Supplier Industrialization Management

Ensuring that suppliers can meet production, quality, and delivery requirements as a company transitions from product development to full-scale manufacturing. It integrates supplier capability assessment, process validation, quality control, and continuous improvement strategies to align supplier performance with business goals.

Acquired SkillsManufacturing Engineering

Focus on designing, optimizing, and improving manufacturing processes, systems, and equipment to efficiently produce high-quality products. It integrates principles from mechanical, electrical, industrial, and materials engineering to ensure cost-effective, scalable, and sustainable production.

Acquired SkillsQuality Assurance

Ensure that products, services, and processes meet established quality standards and customer expectations. It focuses on preventing defects, rather than detecting them after production, by implementing structured methodologies, standards, and continuous improvement practices.

Acquired SkillsMy Work

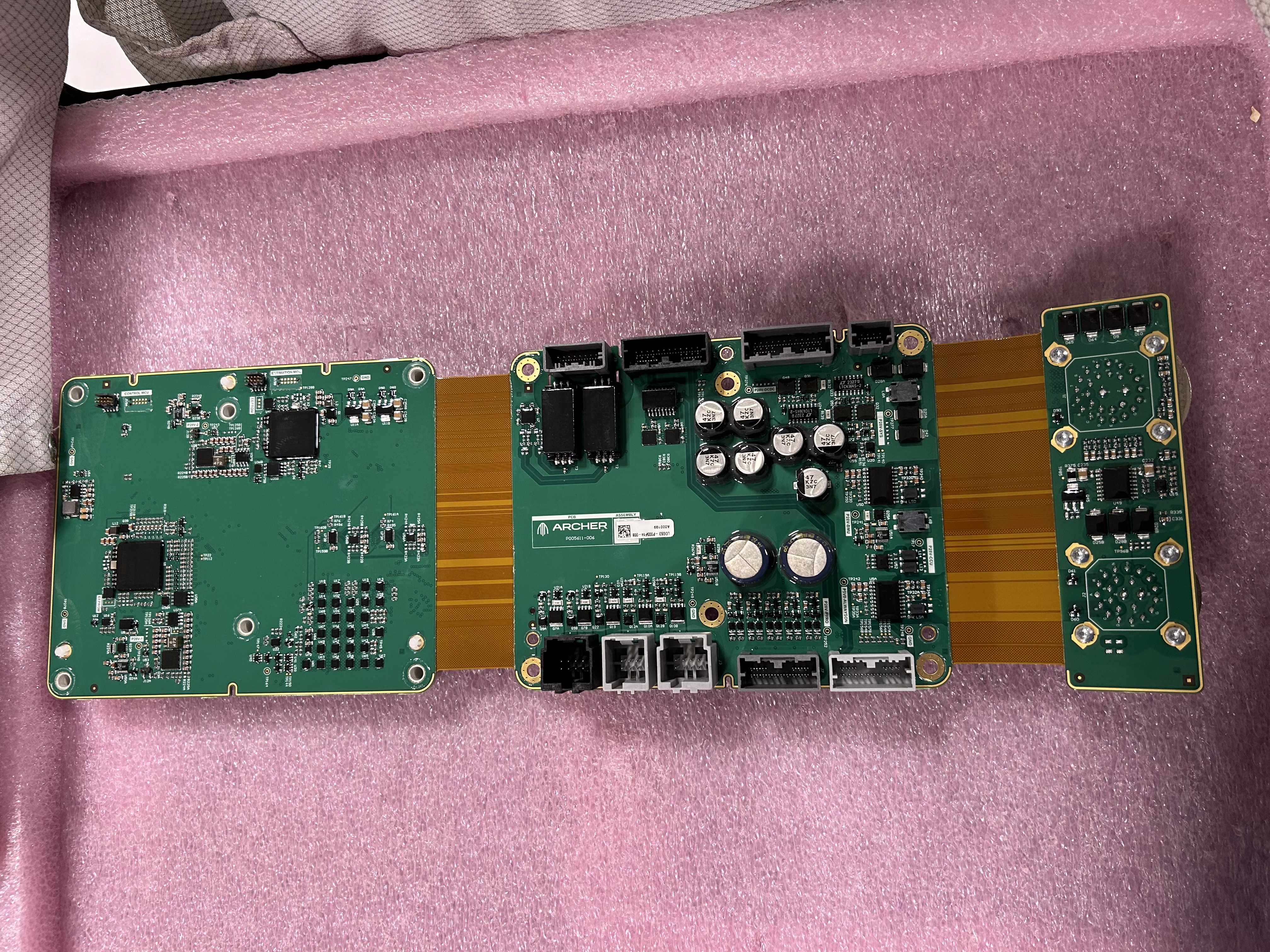

Printed Circuit Board Assembly

During SMT line downtime, I optimized the production process to meet increased demand for PCBs and implemented a new prototype PCBA. By adjusting machine settings and streamlining workflows, I maintained output levels, while also gaining insights for future prototypes.

2025 Sebastian Kokar